New technology which blasts dry ice onto the train tracks to clear away fallen leaves will be trialled by a regional rail operator this autumn.

A Northern train fitted with cryogenic cleaning equipment, known as Cryogrip, will run on specific routes to help clear the line and minimise disruption.

The train, which will not be carrying passengers, is due to run along the line between services in Northern's timetable.

Developed by engineers from the University of Sheffield, it works by firing dry ice pellets at the railhead, in a stream of air at supersonic speed.

Any leaves on the line are frozen and then blasted away as the dry ice pellets turn back into a gas.

The technology has previously been tested on a heritage railway line run by volunteers in Yorkshire – but this is the first time it will be tested on a line used by Northern services.

If the trial is successful, Cryogrip may be used on trains carrying passengers in the future.

Rob Cummings, Northern’s seasonal performance improvement manager, said: “Some people like to make jokes about wet leaves on the line. But when you have steel wheels running on a steel rail, any slippery substance that affects the grip is a big problem.

“There is a comprehensive plan in place to help our train crews deal with this, which includes forecasting, extensive mapping, railhead treatment trains and sanders.

“We are also keen to find out whether the cryogenic cleaning equipment is another effective tool which can be used on other parts of our network."

Roger Lewis, professor of mechanical engineering at the University of Sheffield, said: “Our track cleaning system could revolutionise how we clean the UK’s railways, cut delays for passengers and save the industry some of the millions it loses to leaves on the line every year.

"The testing with Northern is a vital step towards the system being used more widely on lines across the country.”

Thousands of tonnes of leaves fall every autumn and they are dropping earlier this year, following the warmest summer on record.

When they are compressed in wet weather, they form a thin, slippery layer on the rail which can cause trains to slide.

Drivers must pull away more slowly and brake earlier for stations and signals to make sure they stop in time. This can lead to longer journey times and delays.

Northern, which runs services through both Ilkeston and Long Eaton Railway Stations, has mapped out the routes which are usually covered with leaves when the weather turns, and makes sure drivers receive the latest guidance and regular weather forecasts so they can navigate the difficult conditions.

The operator works closely with Network Rail, which runs railhead treatment trains along the lines six days a week. They blast leaf mulch off the tracks and apply a gel – containing a mix of sand and steel grains – to help services run smoothly.

FREE parking to be available for ALL of December

FREE parking to be available for ALL of December

Mayor delivers on pledge to boost tourism and investment in the East Midlands

Mayor delivers on pledge to boost tourism and investment in the East Midlands

CCTV image released as part of investigation into knifepoint robbery at Ilkeston petrol station

CCTV image released as part of investigation into knifepoint robbery at Ilkeston petrol station

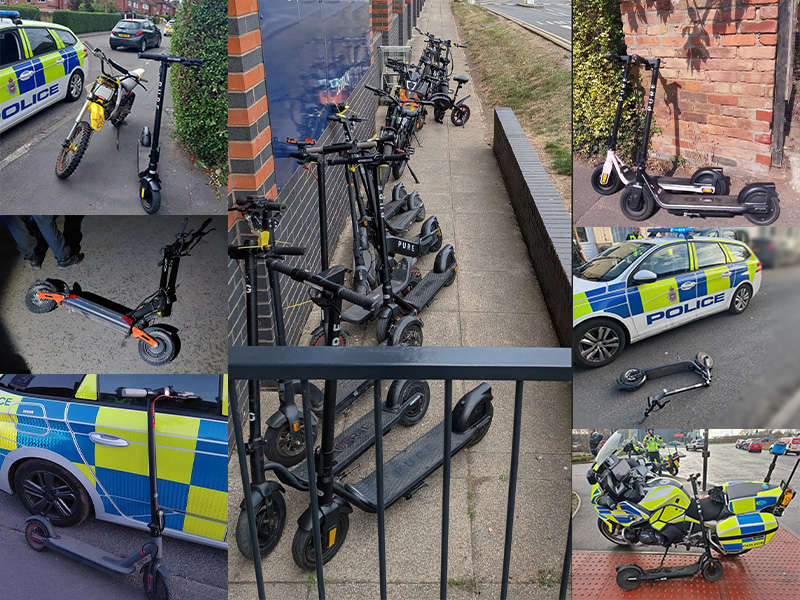

Is an e-scooter on your Christmas list?

Is an e-scooter on your Christmas list?

Derby rail industry on track as PM announces £400m worth of deals for trains, planes and submarines at G20 summit

Derby rail industry on track as PM announces £400m worth of deals for trains, planes and submarines at G20 summit